ADM plant inspections include evidence-based remediation plans with high-quality client support throughout the project’s lifetime.

If you have a complex mechanical engineering problem that needs solving, we’d like to help you.

Proserpine Mill | 2021

Client: Wilmar

ADM and a local design and drafting company conducted a thorough inspection of the Proserpine Mill boiler room to examine remediation options. After assessing the damaged and undamaged steel in the room, ADM designed a remediation plan with adherence to relevant engineering standards and client requirements.

At Proserpine Mill, the boiler firing floor and steelwork was showing signs of significant corrosion. Wilmar contacted ADM and asked for an inspection of the room to assess and provide advice on extending the life of the plant.

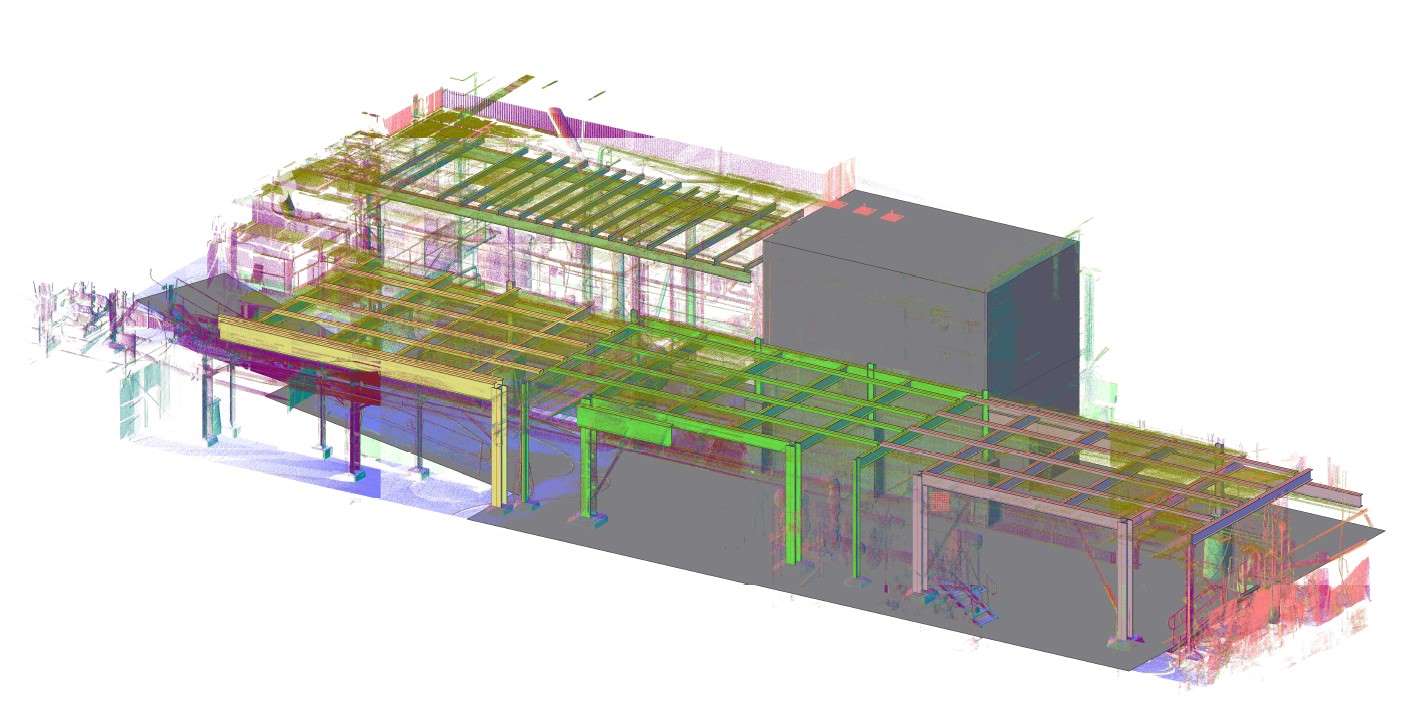

While working in conjunction with a local design and drafting company, ADM conducted a 3D scan and visually inspected the steelwork. ADM also performed ultrasonic thickness testing on select parts of the steelwork. Following this inspection, the collected data were applied to create and analyse a Microstran model. This model was used to determine the accurate condition of the structure for the development of an efficient repair strategy.

The findings were used to redesign the boiler room according to appropriate engineering standards. This proposed redesign was included in a remediation plan to repair and replace corroded sections of the steelwork, allowing for undamaged steelwork to be left in place. Along with a project cost estimation, this plan also included the assurance of continued mechanical engineering assistance during the life of the remediation project.

If you have a complex mechanical engineering problem that needs solving, we’d like to help you.